machining surface finish ra

For example a 125-microinch Ra surface finish will appear nice and smooth. As you know various acronyms are used in machining surface finish.

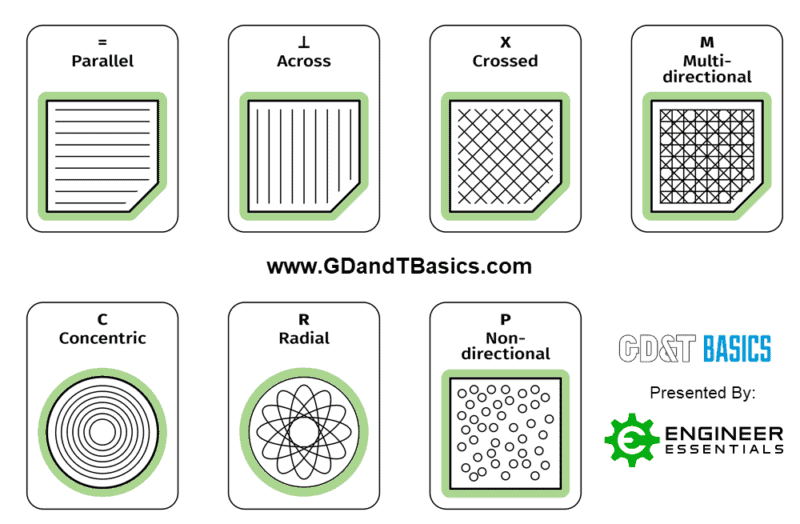

The Basics Of Surface Finish Gd T Basics

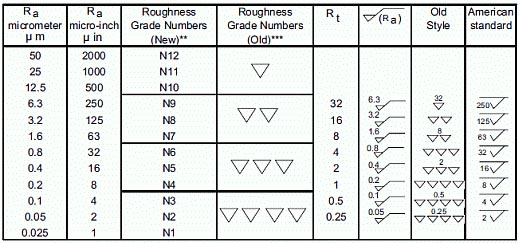

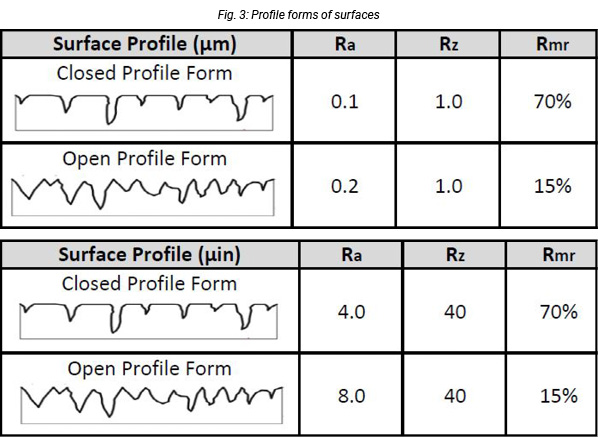

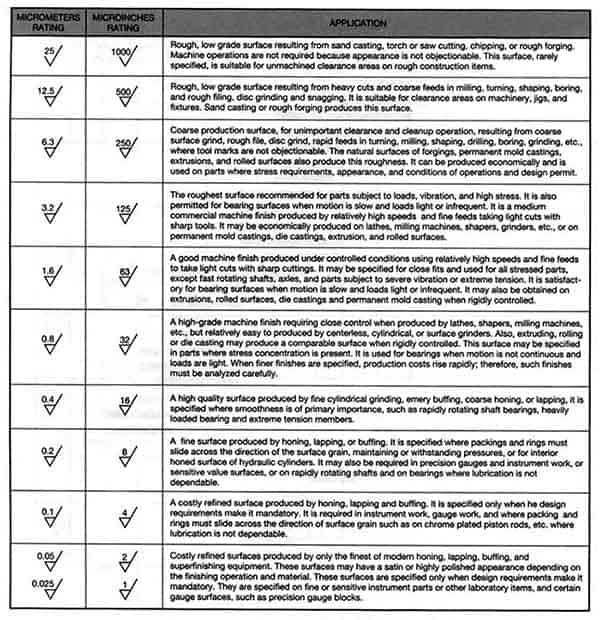

This table will help you understand the impact of the machining process on the surface finish.

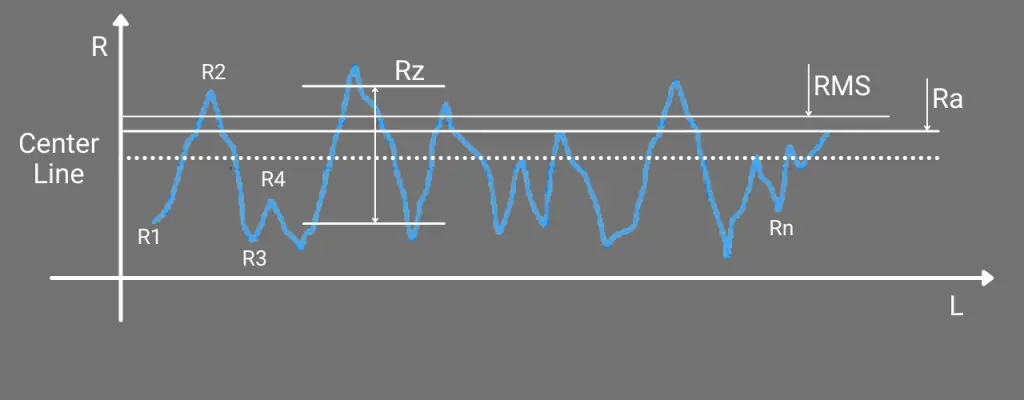

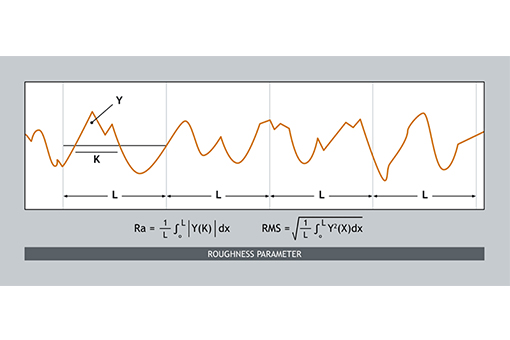

. Ra measures the average length between the peaks and valleys and the deviation from the mean line on the entire. Surface finishes may be increased to 16 08 to. Indicative Surface Roughness Comparisons.

It is considered to be the most acceptable method of measuring surface roughness. Surface Roughness Produced by Different Manufacturing Process. It will have peaks and valleys of varying heights and depths.

According to ASME B461 Ra is the. In our experience the surface finish specified on a drawing does not always reflect what a customer wants. 22 rows The surface finish comparator for milling turning reaming and.

Ra surface finish chart shows the arithmetic average of surface heights that have been measured across a surface. The value of surface roughness therefore is paramount and extra precaution should be taken while performing CNC machining. As an example on a steel part hardened to 60 HRc lapped using silicon carbide 500 grit a pressure of 250 gcm squared will produce a surface finish of about.

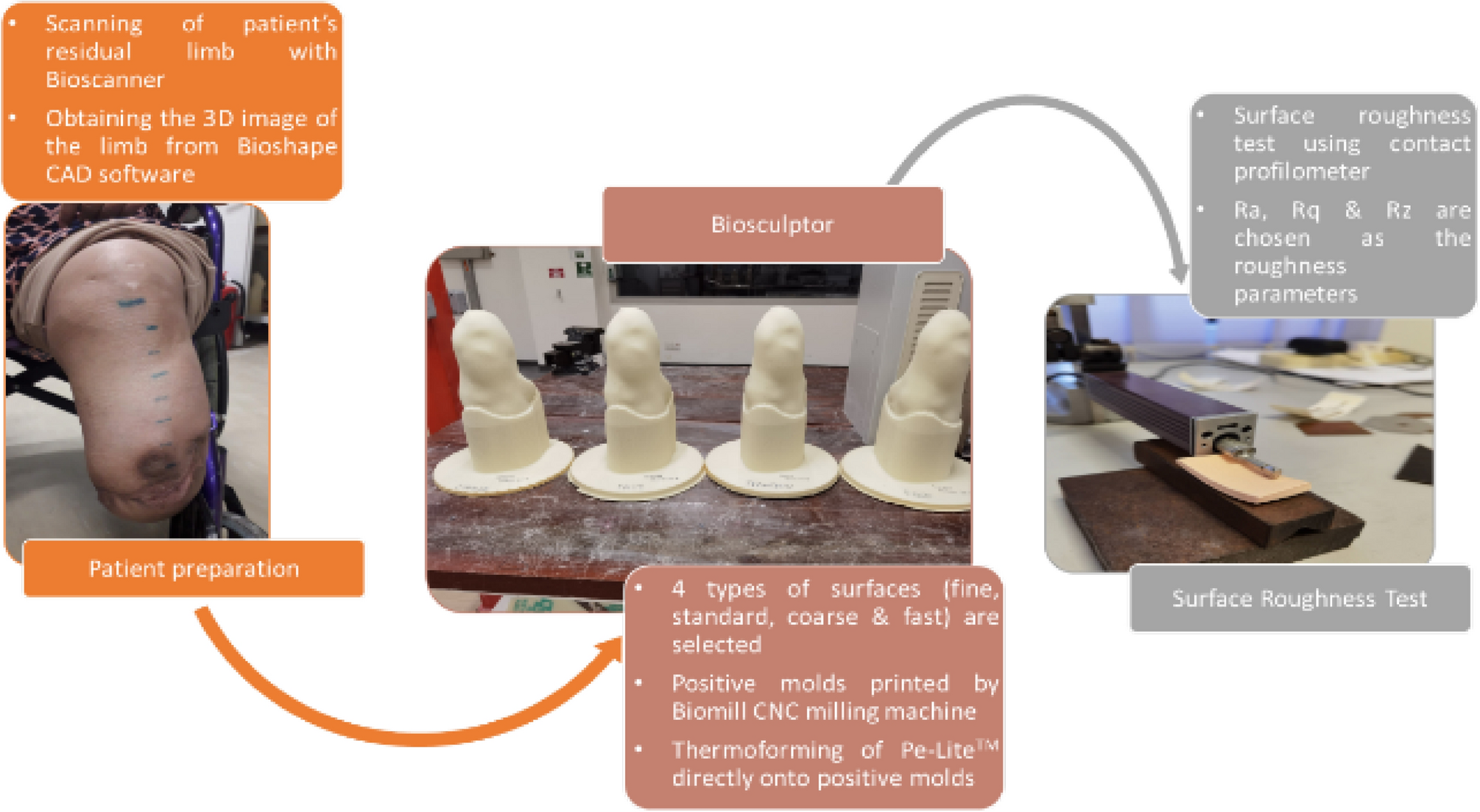

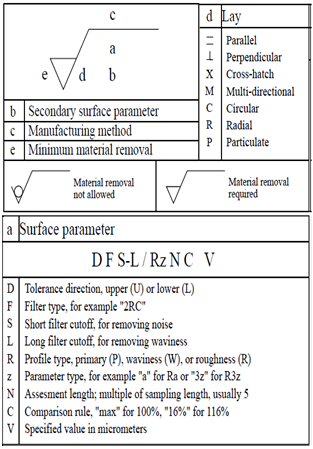

Determining the surface roughness is the first step that should occur after plastic parts are machined. We will discuss below the typical surface roughness units in use in the machining world Ra Roughness Average. The numeric parameter Ra.

Surface Finish Units From RA To Rz. Minorly visible tool marks with a standard surface roughness Ra of 32μm. Looking at the example wavelength below you can see the many peaks and valleys of the bar surface over the.

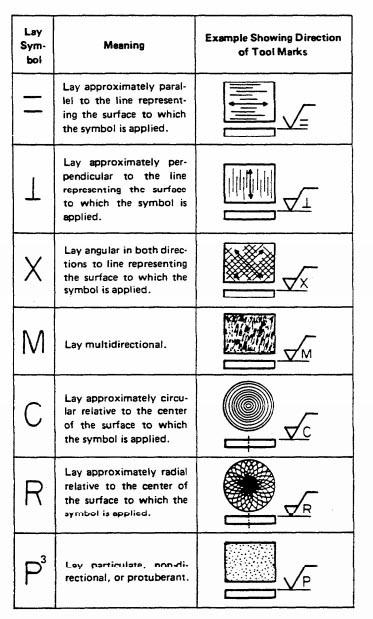

Ra is the most commonly used unit. Ra Average Roughness. Surface finish also known as surface texture or surface topography is the nature of a surface as defined by the three characteristics of lay surface roughness and waviness.

It is difficult to measure surface roughness without. This is done through measurements by using a. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an.

Grit size and Surface Finish. As already mentioned there are three basic. When you see a machining surface finish chart you may find it difficult to understand the abbreviations.

The value of surface roughness of the machined part is not. Director of Industry Research and Technology PMPA.

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Finish Calculators Convertors And Charts

Surface Roughness For Product Developers Star Rapid

Metrology For Manufacturing Surface Measurement

On Machine Surface Finish Measurement Metrology And Quality News Online Magazine

Beyond Ra Why Surface Finish Matters In Seal Performance Fluid Power Journal

5 Grinding Considerations For Improving Surface Finish Norton Abrasives

Measured And The Predicted Values Of Surface Roughness Ra And Rz And Download Table

What Metal S Surface Finish And Surface Roughness China Piping Solution Supplier China Piping Solution Supplier

Typical Ranges Of Surface Finish From Common Machining Processes Download Scientific Diagram

Complete Surface Finish Chart Symbols Roughness Conversion Tables

How To Distinguish Cnc Machining Surface Roughness Between 6 3 And 0 8 Cnc Machining Pcbway

Analysis Of Surface Finishing Processes A Review Research Journal

20 Typical Surface Finish For Basic Machining Operations Download Scientific Diagram

China Wholesale Price China Roughness Tester Machine Surface Roughness Stand Comparator Kairda Factory And Manufacturers Kairda

Selecting Right Surface Roughness For Cnc Machining Xometry Europe

Spi 0 1 To 3 2 Ra Micro M Surface Finish Nickel Surface Finish Comparator 06558266 Msc Industrial Supply